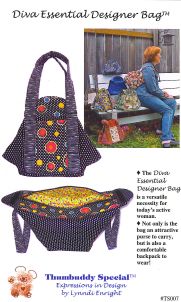

Because I plan to use my Diva bag on an upcoming trip (and because I like stuff like this!), I added some traveler-friendly security features.

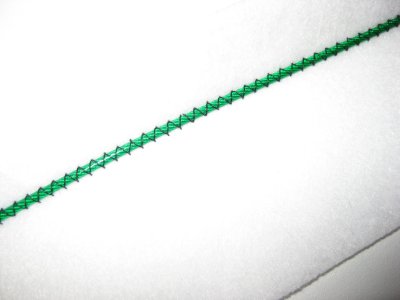

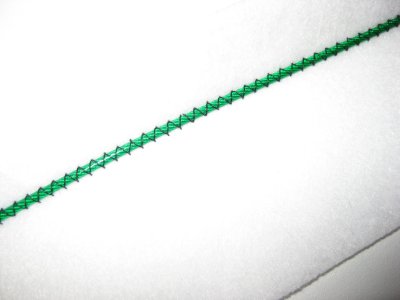

The first modification was putting slash-proof wire into the straps. I bought vinyl coated galvanized wire at Home Depot, and had it cut to length at the store. Then I stitched the wire onto the interfacing for the strap interfacing, zigzagged carefully over the cable. Very carefully — if the needle hit the cable, it would break, and likely go flying, which could be nasty.

Once this was done, I assembled the straps according to the instructions, which have you fold the outer edges of the fabric toward the middle. If you’re cutting your straps from patterned fabric, you’ll want to make sure that you’ll get the results you want by checking the way you’ll be folding your material before you cut! With a solid color, this wasn’t an issue, of course.

Then it was on to the pockets. The larger front pocket has a hidden phone pocket inside, so that’s done first. It’s actually sewn to the front of the bag, and later hidden by the front pocket:

I added the strap and buckle. No way my phone’s hanging out without some kind of restraint. My pleat is the reverse of the one shown in the pattern directions; it doesn’t make any difference — I just prefer this one.

Once you’ve completed the phone pocket, you place the large exterior pocket over it, baste the edges together, and add the straps down each side:

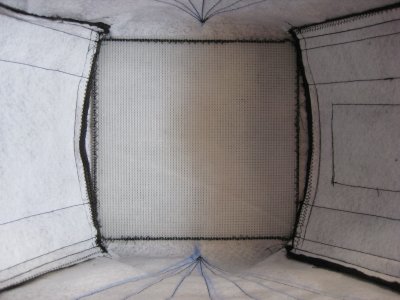

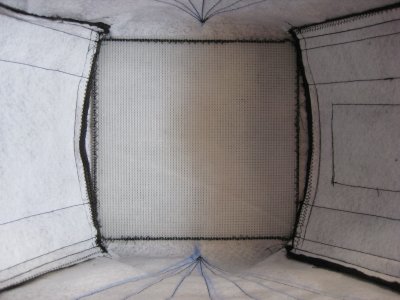

The other side of the bag is done the same way, only the pocket is smaller. Once the straps are attached to the front and back of the bag, it gets assembled just like the lining, except that there aren’t any pockets on the outer sides of the bag. Because I didn’t iron-on my interfacing (I’m sewing with nylon, and just thinking about melting interfacing to nylon gives me a coronary), I quilted the sides of my bag to hold the interfacing in place:

These side pieces fold up accordion-style, so fan-shaped quilting seemed like the right thing. It’s pretty obvious that I’ve never machine-quilted before, isn’t it? Mr. Noile liked that herringbone effect very much, though, and pointed out that it was perfect with the design. I’m going with that thought.

Once the main part of the exterior is assembled, you put a piece of mesh screening in the bottom of the bag. In keeping with my “slash-proof” theme, I sewed two layers of aluminum screening to the underside of the mesh, zigzagging (carefully) around the rough edges.

I tacked four small, M&M shaped buttons to each corner of the base of the bag, through the outer layer of the bag, and through the screen and mesh, to hold the mesh in place. The instructions imply that you’ll be able to tack the mesh to the seams of the bag, but it’s too small to allow that.

The screening won’t prevent my bag from being slashed on the sides, but the sides aren’t likely to cause spillage the way slashing the bottom does. And they’re much harder to get to than the bottom, if you’re looking for a dramatic way into someone else’s purse.

Mr. Noile suggested that, next time, I cut the mesh in half crosswise, and zigzag the pieces together so that it will bend in the middle when the bag is carried. I think that’s smart — the mesh would still provide a base, but the bag wouldn’t be as bulky when carried (unless you really stuff it).

Once the front and back are attached, and the sides are sewn up, and your mesh is in place, the main part of the exterior of the bag is finished:

At this point, you tuck your lining inside, and prepare the “zipper sandwich” that will close the main section of your bag. The zipper excess just gets cut off, and the raw edges on each side are finished with extension flaps that you use to close the bag for carrying. Here’s how the sandwich looks assembled and attached to the bag, before the zipper is trimmed:

The flaps use pattern piece D, as well as an interfacing piece. For some reason, though, the curve on the interfacing piece doesn’t match the curve on pattern piece D. I drew my own, and recommend you, do, too.

Here’s how they looked once they were sewn to the bag:

These flaps are assembled off the bag, but next time, I think I’ll get a better result if I first sew one flap to the bag along the bottom edge, and then stitch the second flap piece to the one already on the bag. Assembling them separately and then fitting them over the raw edge of the bag was a bit of a pain.

(That strap that shows above is the one that secures my phone in the hidden phone pocket.) I didn’t much like the look of this flap — if you use a patterned fabric, it will probably look great, but ugh, this looks so . . . utilitarian?

So I scrounged around and found this trim:

Hook and loop tape is used to close these flaps. I’m already concerned that this skinny strip won’t be able to take the heat over time — when the bag’s full, there’s a fair amount of stress on it. One solution might be to use extra wide, extra strong hook and loop here — covering most of the flap. Or maybe some other kind of fastener is indicated; I haven’t really made up my mind.

Matching the flaps up perfectly when closing them is a bit of a pain for we OCD types, too. Next time I might just cut these in a rectangular, shorter height, shape. Though I admit that the flap curves do work well with the shape of the rest of the bag.

Closed, the bag is about 8 inches by 12 inches at its base — that includes the sides, which stick out past the front a bit:

The strap length is perfect on me — easy to wear, and also easy to carry. Made in my nylon, it’s also incredibly light, but strong. Here’s the interior, stuffed for a trip:

What’s there? Starting at the left and clockwise, a phone, a folding toothbrush, a mini-tripod, a Moleskine City Notebook (don’t leave home without it!), small pocket with stevia packets, the “hidden” pocket with my wallet, etc., a mini-flashlight, extra mini-pens, my Moleskine planner, and a small pocket with a spork, soap leaves and lip balm. Attached to the D rings are my Nintendo DS (sudoku and brain games to go) on one side, and a small zip bag for personal items (comb, towelette packets for restrooms without tissue, etc.). On the bottom of the bag are a silicone cup stuffed with a bandanna and a small packet of nuts, and my clip-on sunglasses.

There’s a lot of room, but you can’t quite use it all, since folding the bag to close it reduces the volume significantly. My small notebooks interfere with the folding a bit — I just push them toward the center, though, and it works out fine. Those of you who travel lighter won’t have an issue with this.

In the outer pockets are a fold-out pocket city map and a packet of tissues; I’ll have a 12 ounce thermal drink container in the larger outside pocket on most days.

As the pattern promises, you can wear the Diva as a backpack — very handy when you need both hands for a few minutes (or even longer):

Though it admittedly looks a little odd from the side:

I had a wonderful time making this bag, and loved the very clear, step-by-step directions. There aren’t any steps here that are difficult, and, as long as you label your pieces, assembly should go very smoothly, even for a novice. The Diva is a cleverly designed bag, and I’m expecting it to be very useful for everyday as well as for trips when I want everything but the kitchen sink with me while I’m out all day exploring.

Follow-up: After a week in Washington, DC, I can report that this is a wonderful light bag that mostly fulfilled my requirements very well. However, when I travel, I tend to carry a whole lot of stuff, and most of it would do better in a flatter bag. I’m seriously considering making this bag again, and making these changes:

* reducing the width by three to four inches, and widening the length by about four inches to make a much flatter bag

* taking the deep pleats out of the phone pockets — they’re way too big for my phone

* making the closure flaps rectangular, and using a different method to stiffen and close them. As I’d suspected, when the bag is really packed, the hook and loop can’t quite keep things together.

* switching the inside pockets so that the larger ones go behind the front and back panels, instead of along the folding edges. This would put one of these pockets against the “secret” pocket, which might require a more substantial closure on the “secret” pocket.

* placing the inner phone pocket, and possibly several other smaller ones (maybe one specifically designed for pens, and another for my spork and chopsticks) along the folding sides

* adding an umbrella pocket on the underside of the bag (with a closure) (Another Mr. Noile suggestion!)

* adding a webbing strap under the bag to give my hand a natural place to hold my overstuffed bag when it’s on my shoulder

* putting hook fastener on the top of one strap, and loop fastener on the top of the other so that they hook and loop together on my shoulder

As a final note, I wish that Lynndi Enright had been a little more careful with her branding. When I post this to Pattern Review, how do I post it? Under “Expressions in Design” “Thumbuddy Special” or “Lynndi Enright”? Every one of these appears on the pattern envelope, but none of these are listed on Pattern Review’s drop-down company listing. Unfortunately, Pattern Review’s search system isn’t sophisticated enough to overcome a challenge that doesn’t involve exact names.

“Thumbuddy Special” is particularly bad, not only because you have to remember that it’s said as if it were a lisp, but then you have to wonder whether it’s got two letters “b” or not. Not to mention that, bizarrely, it’s not a unique name.

Searching on Google for “Diva Essential Designer Bag” is complicated, too — try it, or just imagine how many hits you get with the words “diva designer bag”. All of this makes finding the patterns somewhat difficult.

Designers, beware! A unique, specific, descriptive name is a really good idea if you’re trying to sell a product people will want to find on the internet.

Previously:

Diva Essential Designer Bag

Diva Bag: The Lining